Chemical Testing

1

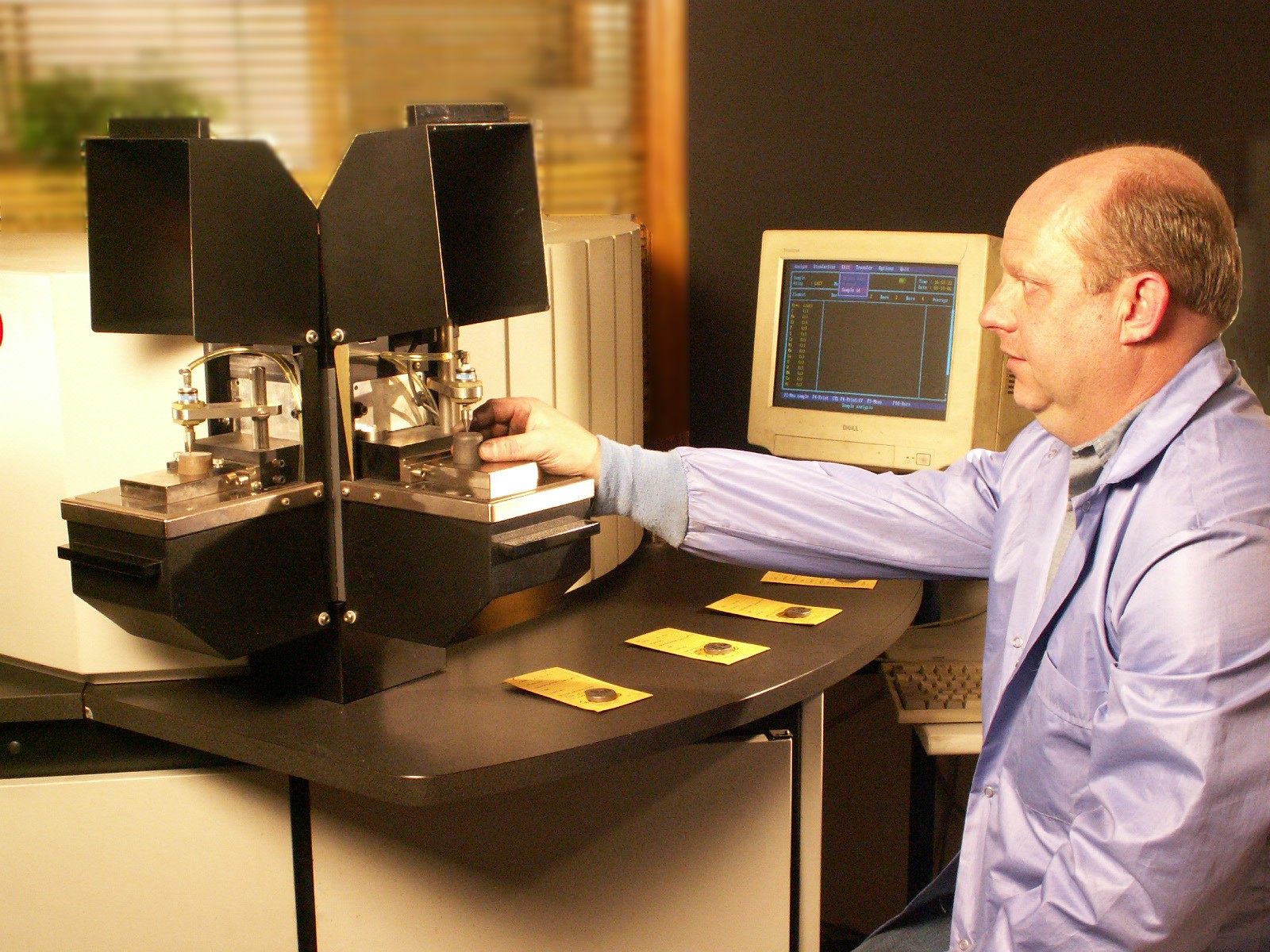

1Spectroscopy

When quick results are needed, spectrographic analysis by APL Inc. is the answer. Both speed and repeatable accuracy are gained through the use of a computer-controlled, direct reading, optically emitting, ark spark spectrometer. The spectrometer will perform its analysis on the majority of the solid samples submitted, and is programmed to cover virtually all of the standard engineering alloys. A digitally generated data file of all elements required in ASTM standards is retained for future reference.

Carbon, Sulphur, Hydrogen, Nitrogen, and Oxygen Analysis

Traditional Spectrographic techniques for the determination of carbon, sulfur, nitrogen and oxygen can be inherently inaccurate. Thanks to the use of LECO analyzers, APL can determine the concentrations of these elements in a sample with an exceptionally high degree of accuracy.

2

2 3

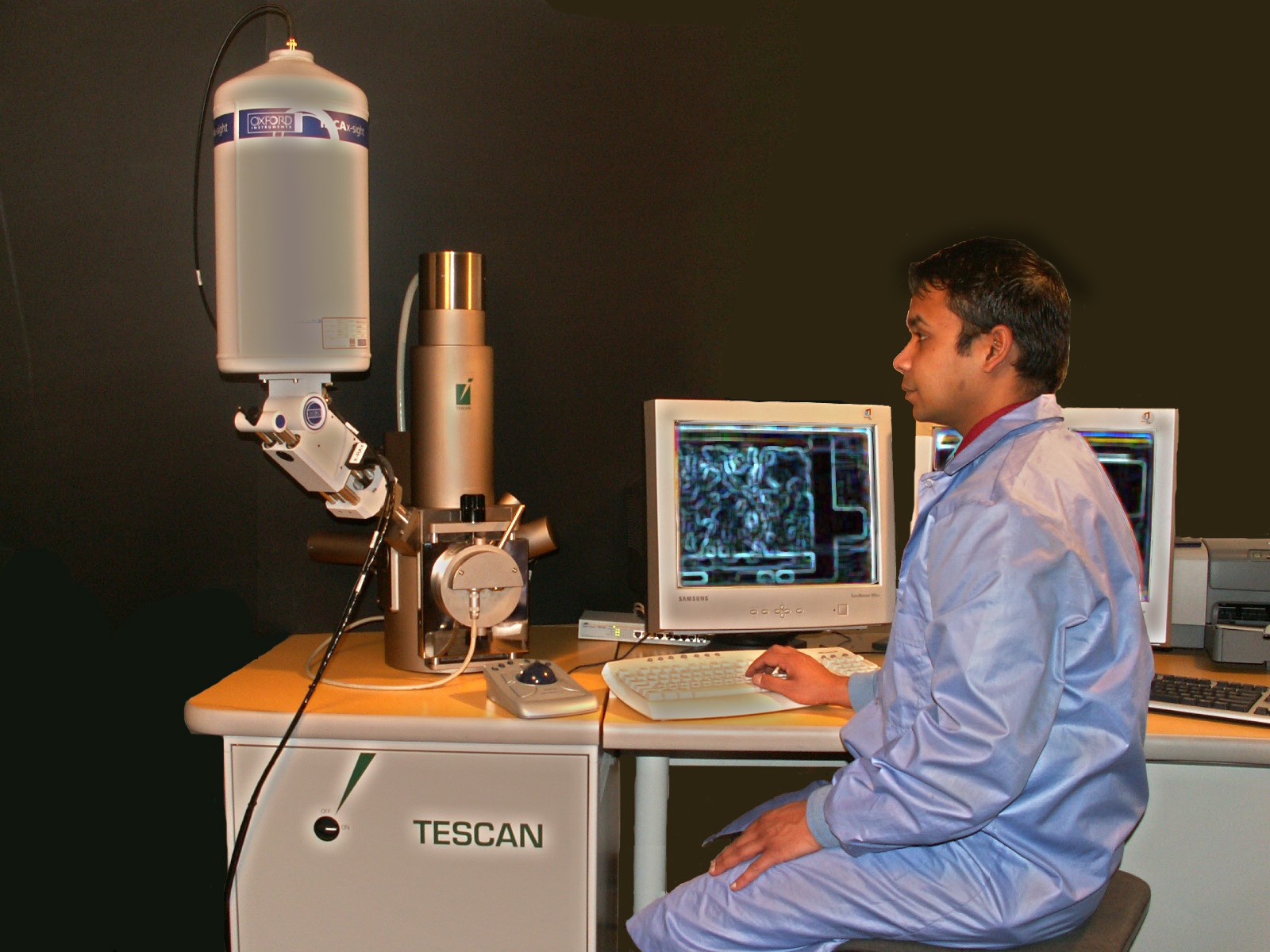

3XRF and EDS Analysis

The techniques of Energy Dispersive Spectroscopy (EDS) applied in conjunction with a scanning electron microscope (SEM) are used in determining data on a range of valuable parameters:

- Mode and origin of failures

- Corrosive element determination

- Microscopic chemistry

- Microscopic defect

- Surface analysis

- Particle analysis