Metallography

1

1Failure Analysis

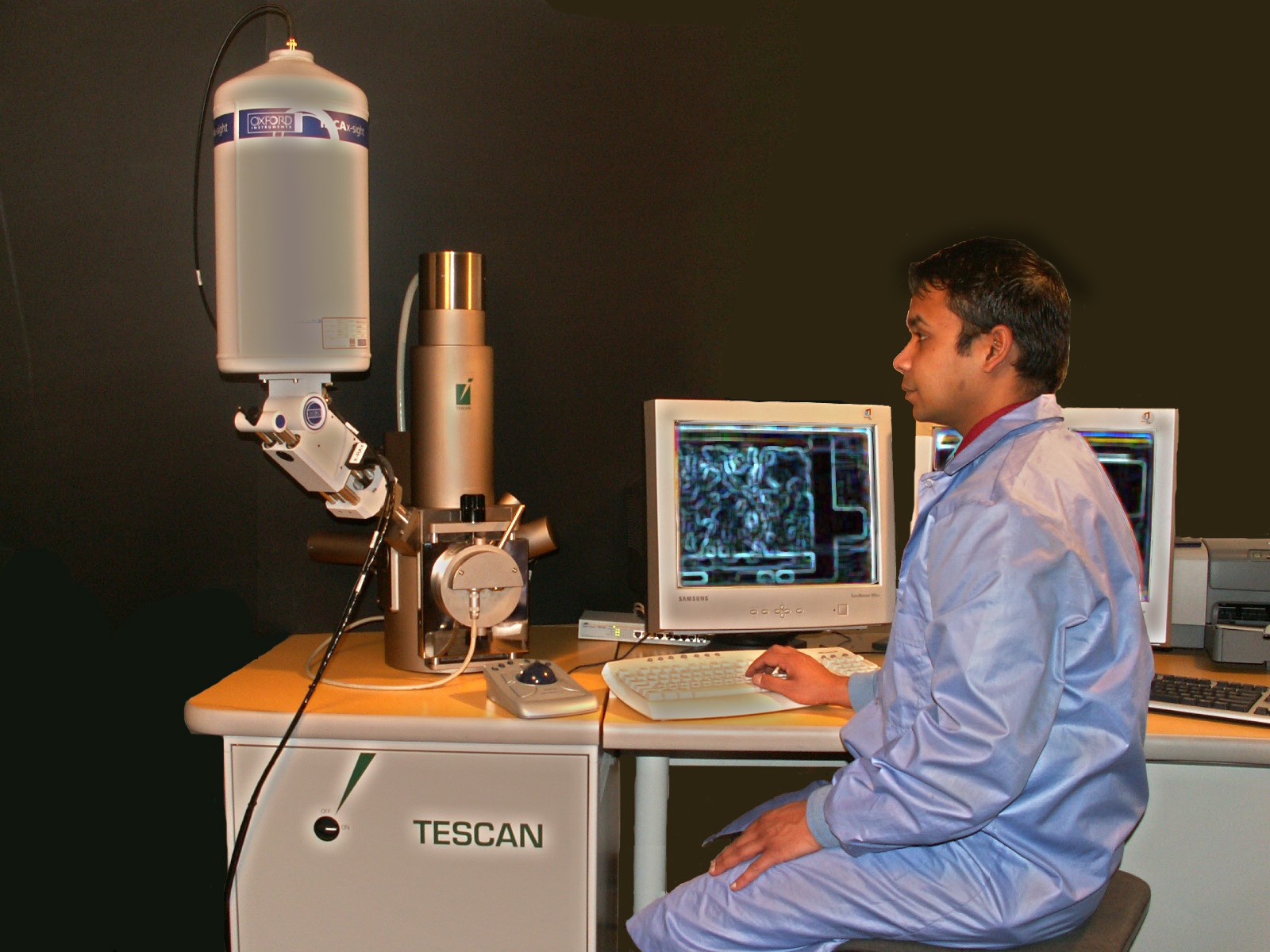

Failure analysis is the process used to investigate the failure of a metal component. Identification of failure modes..which can include physical abuse or exposure to a hash environment ... is the key to diagnosing failures and correcting processing issues. APL is uniquely qualified and equipped to perform failure analysis on an array of components and metallic materials. We can assist your plant personnel in both accurately identified the correct cause of a failure and initiating corrective actions. APL is equipped with all the tools traditionally used in failure analysis:

- Scanning Electron Microscopes (SEM)

- Optical Microscopes

- Chemical Analysis Facilities

- Mechanical Testing Equipment

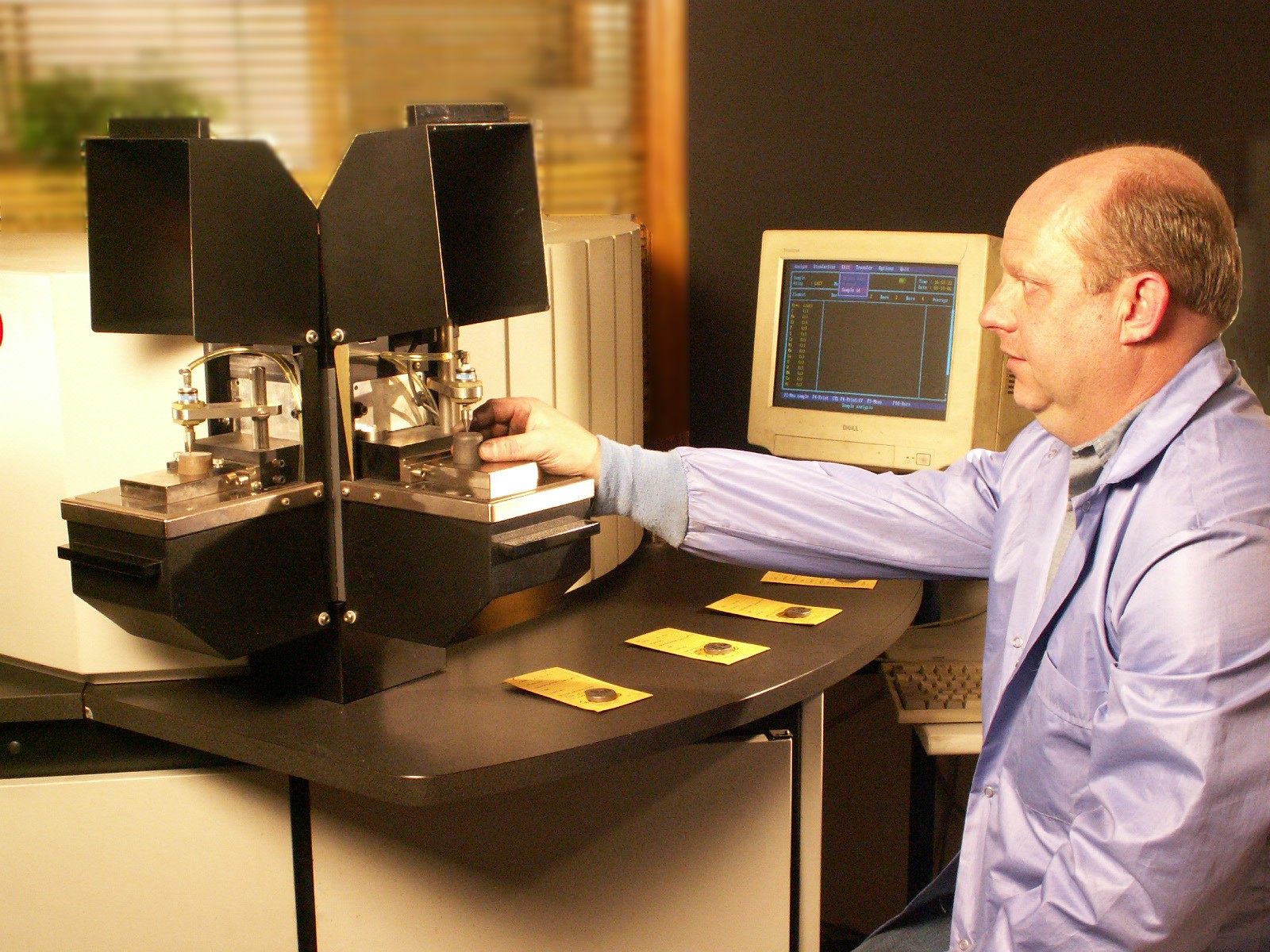

Image Analyzer

- Measurement of Inclusions

- Nodular Count in Iron

- Coating Thickness

- Grain Boundary Detection

- Grain Size

- Dendrite Arm Spacing

- Inclusion Content Analysis

2

2 3

3Metallography

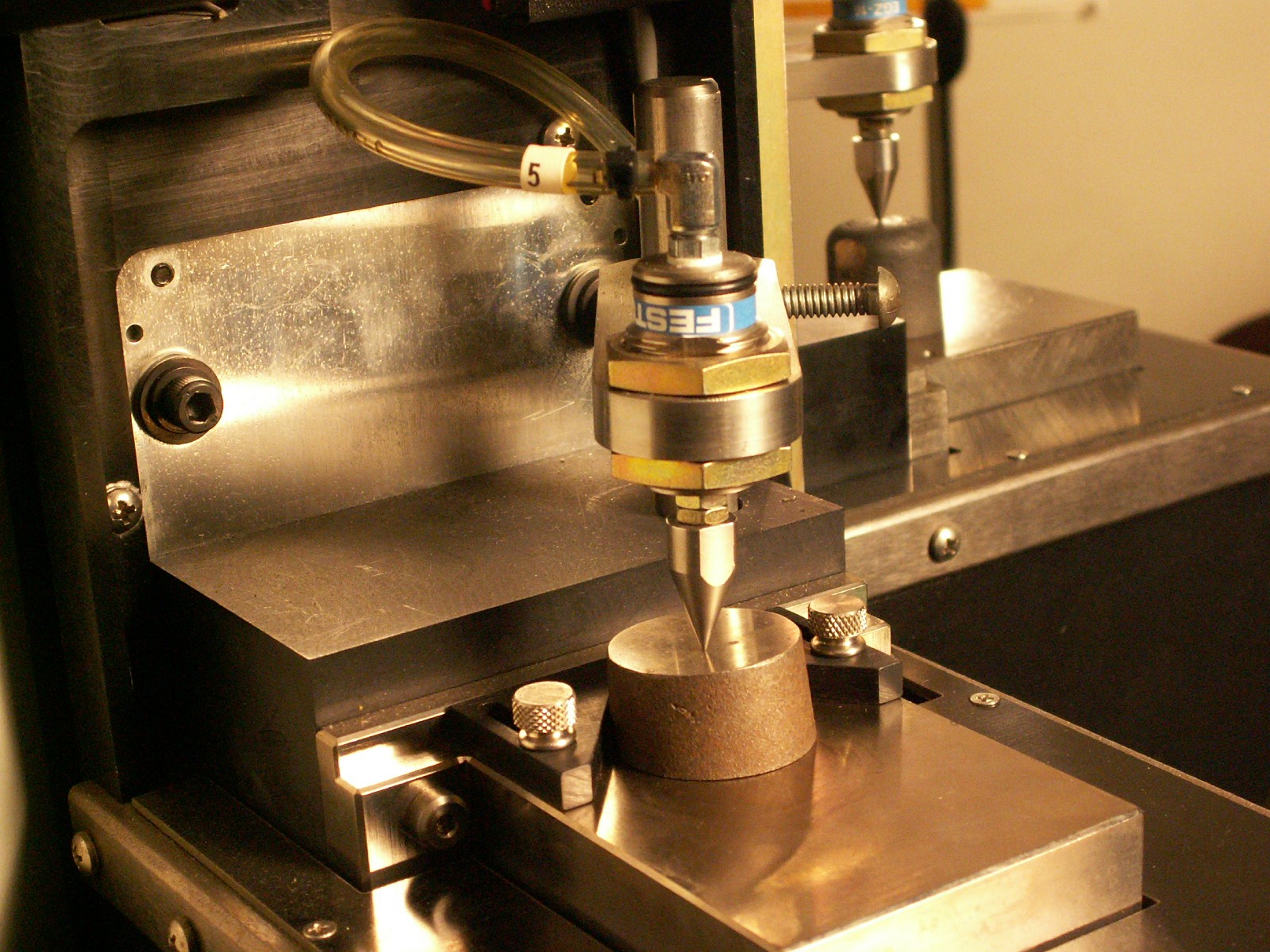

The key to solving metallurgical problems is examining and evaluating the microstructure of the material through the application of metallography. Metallography is the science of dealing with the constitution and structure of metals and alloys as revealed by the unaided eye or by instruments such as an optical microscope. APL has the equipment and the expertise needed to solve specific metallographic experts offer solutions to your problems by examinig photographs and/or photomicrographs for:

- Grain Size Determination

- Size Distribution

- Phase Area Distribution

- Microhardness Determination

- Inclusions Rating

- Heat Treatment

- Crack Evaluation